Reverse Engineering Car Tail light

THE PROBLEM

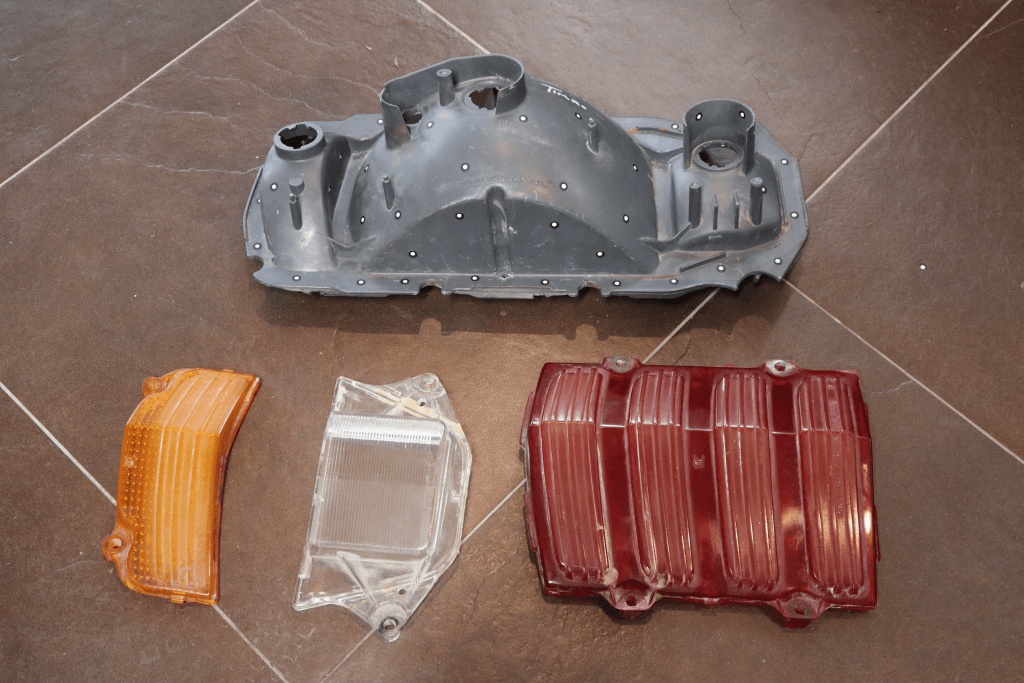

Our client was restoring a classic car, and since replacement parts for such a classic are extremely rare, our client decided to have a new ones manufactured. However, the original would first have to be reverse engineered which is where our highly accurate scanners proved invaluable.

THE SOLUTION

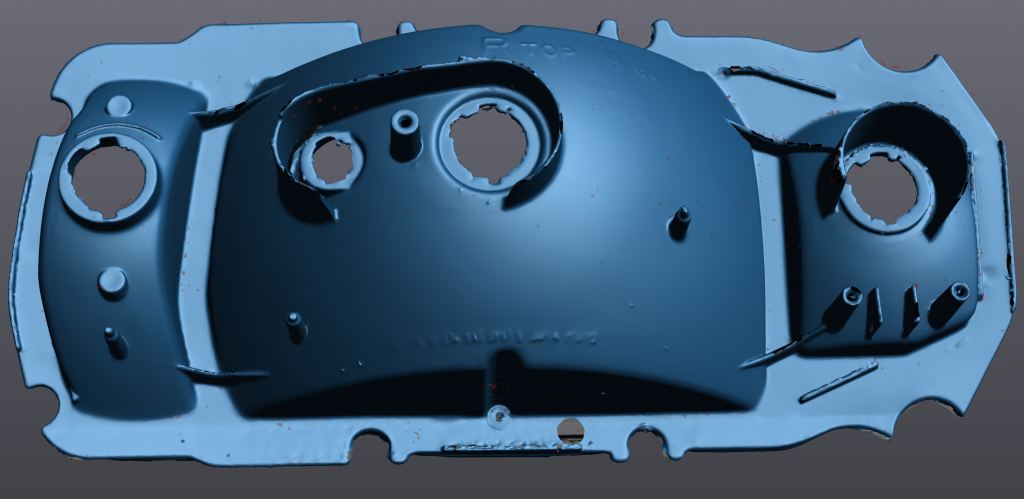

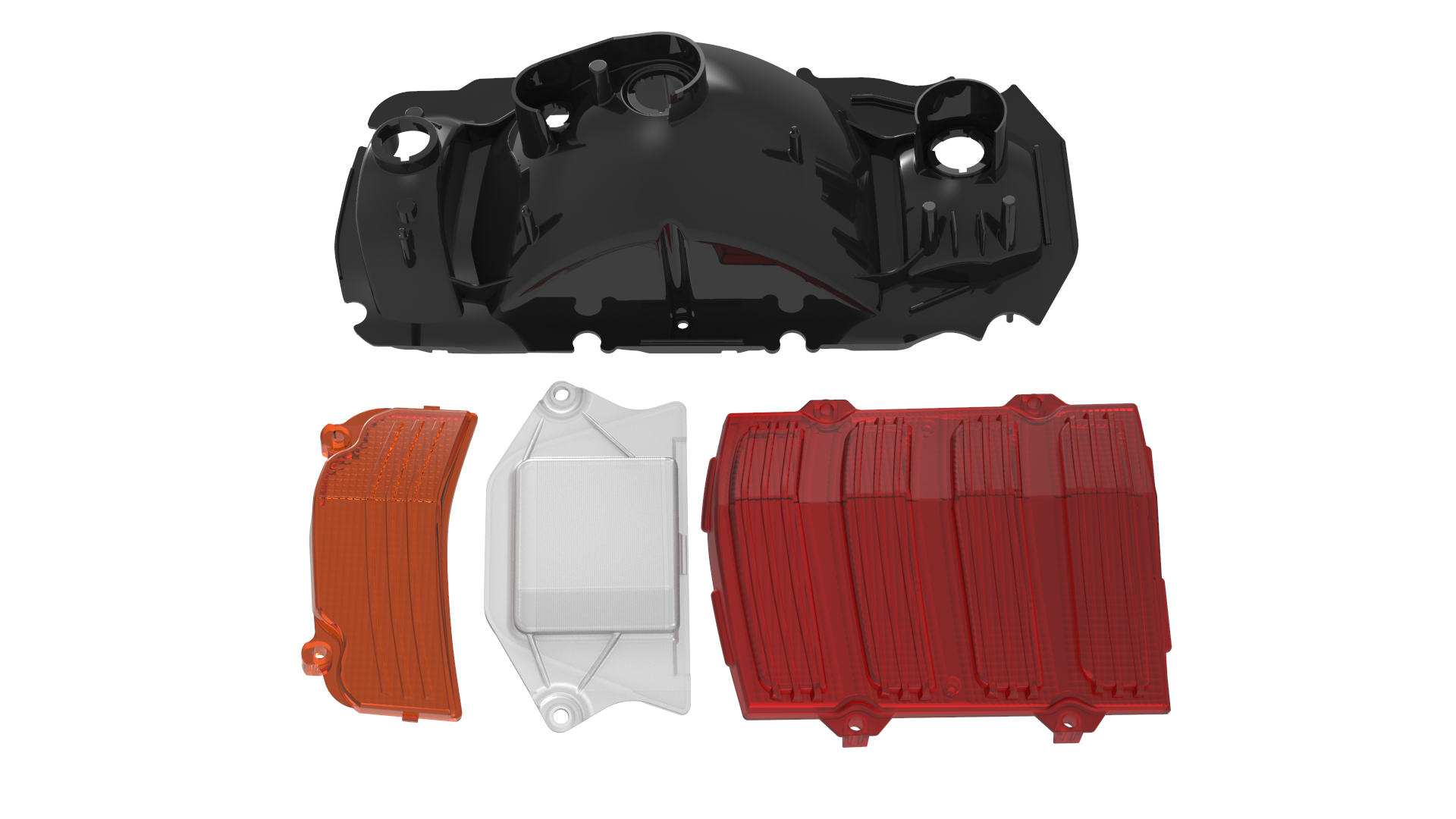

3D scanning technology offers a lightning-fast and highly effective way to transform complex automotive parts into digital models. First, we scanned the tail light parts using our high-tech Creaform 3D scanner, which allow us to rapidly capture the complex geometry of the part with absolute precision. We then used Geomagic Design X to convert the scan data into a parametric CAD model.

THE RESULT

Our client was delighted with the reverse engineered tail light, which can now be manufactured and affixed to his car to complete his restoration project. Should the client require subsequent modifications to the design, this will be simple to achieve using our powerful suite of 3D software.

This case study shows that 3D scanning techniques can significantly improve upon the speed and effectiveness of traditional manual methods when it comes to replicating components for vehicle restorations, as well as a wide range of other applications. For help with your next restoration project, simply contact the friendly team at Absolute 3D today.